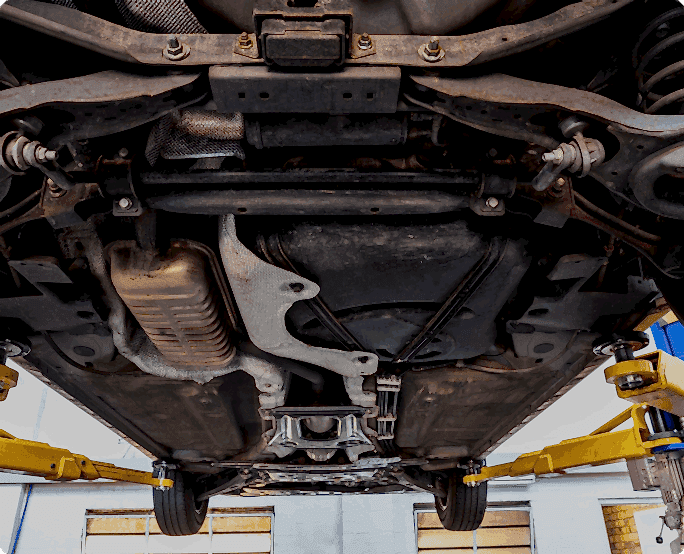

🔹 1. Cleaning and Preparation

Before the application, the underside of the vehicle, door interiors and chassis are cleaned and cleaned from dust and dirt.

🔹 2. Rust Control and Pretreatment

Existing rusty areas are cleaned with special chemicals and anti-rust materials are applied.

🔹 3. Rust Preventive Coating Application

Special anti-rust coating is applied to metal surfaces with a spray or brush.

Denser and thicker protective coatings are used for undercarriage and chassis.

🔹 4. Drying and Fixing

After application, the drying process is expected for the protective layer to fully adhere to the surface.

Rust prevention is a special coating and protection process to protect the metal surfaces of the vehicle against corrosion and oxidation. Rusting can occur on metal surfaces due to moisture, salt water, road salt, mud and weather conditions. The anti-rust treatment protects the undercarriage, door interiors, chassis and metal parts of the vehicle, making them more durable and durable.

✅ Protects Metal Surfaces Against Corrosion

The lower part of the vehicle, chassis, door interiors and other metal parts are protected against rust.

✅ Provides Moisture and Salt Water Resistance

It prevents rusting caused by salt poured on the roads, especially in coastal areas and in winter.

✅ Extends Vehicle Life

Increases the durability of metal surfaces and extends the life of the vehicle.

✅ Increases Bodywork and Chassis Durability

Protects the structural integrity of the vehicle by strengthening critical areas such as the chassis and undercarriage.

✅ Invisible and Effective Protection

After application, there is no change in the external appearance of the vehicle, but a strong barrier against rust is created.

✅ Contributes to Sound Insulation

Anti-rust coatings applied to the undercarriage also slightly reduce road noise and increase comfort.